Can you anodize aluminum twice.

If you’re looking for can you anodize aluminum twice pictures information related to the can you anodize aluminum twice keyword, you have come to the ideal blog. Our site always provides you with hints for downloading the highest quality video and picture content, please kindly surf and locate more enlightening video articles and graphics that fit your interests.

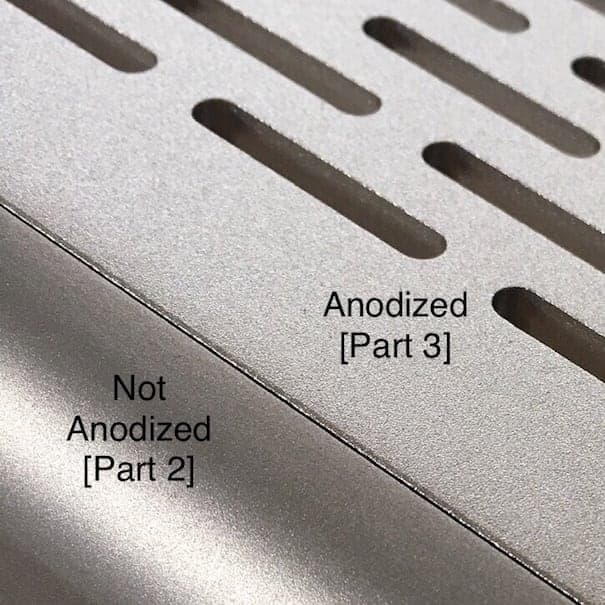

Anodized Aluminum Parts Vs True Hard Anodize Chainrings From wickwerks.com

Anodized Aluminum Parts Vs True Hard Anodize Chainrings From wickwerks.com

Kept unsealed and wet then you can re-start. So it might be theoretically possible to restore the original diameter by anodizing twice as thick the second time around. Hardcoat would be thicker and have a smaller pore unless done at higher temperature and that would protect your aluminum for a longer time than would lower thickness and larger pores. In this video I look at a couple of dye effects.

Type II anodizing process uses sulfuric acid instead of chromic acid.

Anodized aluminum is primarily a specialty aluminum finish that adds durability to aluminum. Kept unsealed and wet then you can re-start. Several examples are shown. Anodized aluminum is primarily a specialty aluminum finish that adds durability to aluminum. The important thing to remember is that the surface must be thoroughly washed and dried before applying the etching primer and paint.

Source: makeitfrommetal.com

Source: makeitfrommetal.com

For restoration of coating performance with good cosmetic finish then items can be re-anodised. This will not restore the appearance but will provide corrosion protection and can be painted. Type II anodizing process uses sulfuric acid instead of chromic acid. Type II anodization is best suited for aluminum but it may also be used for nonferrous metals such as titanium or magnesium. A marbled piece is d.

Yes anodized aluminum can be painted.

Type II anodizing process uses sulfuric acid instead of chromic acid. The important thing to remember is that the surface must be thoroughly washed and dried before applying the etching primer and paint. Either way you should find out as much as you can consult a chemist and make sure to wear protective gear while undertaking this DIY project. A marbled piece is d.

Source: wickwerks.com

Source: wickwerks.com

So really you can anodize stainless but its definitely not a project worth your time. Hardcoat would be thicker and have a smaller pore unless done at higher temperature and that would protect your aluminum for a longer time than would lower thickness and larger pores. If you have anything you want seriously wear resistant you need massive current for type 3 hard coat annodized. Either way you should find out as much as you can consult a chemist and make sure to wear protective gear while undertaking this DIY project.

Source: finishingandcoating.com

Source: finishingandcoating.com

Aluminum and titanium yes. The only issue is that about a thousandth of an inch of aluminum is consumed in building a two thousandth of an inch anodized coating. However there are three problems. You can get clear anodized but its still a light straw gold color.

Source: youtube.com

Source: youtube.com

The bottom line here is you can use oven cleaner to strip the anodize layer or you can make do with drain cleaner to remove anodizing from aluminum. Several examples are shown. Various color combinations are offered. Multiple layers of paint may be necessary.

Kept unsealed and wet then you can re-start. Yes anodized aluminum can be painted. Because Hammack managed to make me intensely interested in something Id previously never really thought twice aboutthe anodized aluminum coatings that. You can get clear anodized but its still a light straw gold color.

In this video I look at a couple of dye effects.

Type II anodizing process uses sulfuric acid instead of chromic acid. Aluminum and titanium yes. This will not restore the appearance but will provide corrosion protection and can be painted. Its a very standard practice to strip and re-anodize Jim and very often its no problem. Because of the need for electrical contact for anodising any existing coating must be removed before items can be re-anodised we do not offer brush anodising.

Source: wickwerks.com

Source: wickwerks.com

Various color combinations are offered. Aluminum anodizing is an electrochemical process in which an oxide anodic layer is chemically built on the surface of the metal. Use chromic acid to produce a thin and ductile anodized layer on an aluminum part. This will not restore the appearance but will provide corrosion protection and can be painted. If you strip the anodizing the diameter will be down to 09998.

When you strip that coating the aluminum is lost it doesnt come back. Various color combinations are offered. Its dunked in dye RIT dye works and then boiled to seal in the color. Technically anything can be anodized.

In this video I look at a couple of dye effects.

If you were to anodize the second time to a thickness of 00004 the diameter after anodizing would be 10002 again. Aluminum anodizing is an electrochemical process in which an oxide anodic layer is chemically built on the surface of the metal. Anodizing provides surface corrosion protection. Anodized aluminum is primarily a specialty aluminum finish that adds durability to aluminum.

Source: makeitfrommetal.com

Source: makeitfrommetal.com

Aluminum and titanium yes. Several examples are shown. The first is the fade where one color fades into another. Type II anodization is best suited for aluminum but it may also be used for nonferrous metals such as titanium or magnesium.

Source: finishing.com

Source: finishing.com

Kept unsealed and wet then you can re-start. However there are three problems. This oxide layer acts as an insulator and can be dyed in a wide variety of colors. It is possible that one batch of 6061 bright anodises better than one batch of 6063.

Source: wickwerks.com

Source: wickwerks.com

Several examples are shown. Several examples are shown. The trouble is unless your Aluminium supplier can tell you before hand the exact composition the final result will not be known until after anodising. Use chromic acid to produce a thin and ductile anodized layer on an aluminum part.

Double anodizing is a multiple anodizing process in which the text and graphics color and background color are dyed and sealed into the aluminum.

You can throw your neighbors annoying yowling cat into a bucket of water and wire it up. Because of the need for electrical contact for anodising any existing coating must be removed before items can be re-anodised we do not offer brush anodising. If the cat is on the receiving end of the electrons youve got yourself an anodized cat. Hardcoat would be thicker and have a smaller pore unless done at higher temperature and that would protect your aluminum for a longer time than would lower thickness and larger pores. Kept unsealed and wet then you can re-start.

Source: finishing.com

Source: finishing.com

You have to chemically. Anodized aluminum is primarily a specialty aluminum finish that adds durability to aluminum. The bottom line here is you can use oven cleaner to strip the anodize layer or you can make do with drain cleaner to remove anodizing from aluminum. It is possible that one batch of 6061 bright anodises better than one batch of 6063. Type II anodization is best suited for aluminum but it may also be used for nonferrous metals such as titanium or magnesium.

This oxide layer acts as an insulator and can be dyed in a wide variety of colors.

You can get clear anodized but its still a light straw gold color. Because of the need for electrical contact for anodising any existing coating must be removed before items can be re-anodised we do not offer brush anodising. If you need functional aluminum parts that will face corression or wear such as aircraft parts or consumer goods this post-processing technique will satisfy your needs. Aluminum and titanium yes.

Source: youtube.com

Source: youtube.com

You can get clear anodized but its still a light straw gold color. Anodizing provides surface corrosion protection. This oxide layer acts as an insulator and can be dyed in a wide variety of colors. The first is the fade where one color fades into another.

Source: wickwerks.com

Source: wickwerks.com

If you were to anodize the second time to a thickness of 00004 the diameter after anodizing would be 10002 again. If you strip the anodizing the diameter will be down to 09998. When you strip that coating the aluminum is lost it doesnt come back. This process produces an abrasion corrosion and chemical-resistant finish.

Source: makeitfrommetal.com

Source: makeitfrommetal.com

The trouble is unless your Aluminium supplier can tell you before hand the exact composition the final result will not be known until after anodising. Hardcoat would be thicker and have a smaller pore unless done at higher temperature and that would protect your aluminum for a longer time than would lower thickness and larger pores. This oxide layer acts as an insulator and can be dyed in a wide variety of colors. Use chromic acid to produce a thin and ductile anodized layer on an aluminum part.

Because Hammack managed to make me intensely interested in something Id previously never really thought twice aboutthe anodized aluminum coatings that.

This oxide layer acts as an insulator and can be dyed in a wide variety of colors. Type III Hardcoat Anodize. Kept unsealed and wet then you can re-start. Aluminum anodizing is an electrochemical process in which an oxide anodic layer is chemically built on the surface of the metal. So really you can anodize stainless but its definitely not a project worth your time.

Source: finishing.com

Source: finishing.com

If you need functional aluminum parts that will face corression or wear such as aircraft parts or consumer goods this post-processing technique will satisfy your needs. Use chromic acid to produce a thin and ductile anodized layer on an aluminum part. Type II anodizing process uses sulfuric acid instead of chromic acid. Multiple layers of paint may be necessary. In this video I look at a couple of dye effects.

Use chromic acid to produce a thin and ductile anodized layer on an aluminum part.

Its a very standard practice to strip and re-anodize Jim and very often its no problem. However there are three problems. This oxide layer acts as an insulator and can be dyed in a wide variety of colors. You can throw your neighbors annoying yowling cat into a bucket of water and wire it up.

Source: finishing.com

Source: finishing.com

Double anodizing is a multiple anodizing process in which the text and graphics color and background color are dyed and sealed into the aluminum. Type II anodization is best suited for aluminum but it may also be used for nonferrous metals such as titanium or magnesium. Use chromic acid to produce a thin and ductile anodized layer on an aluminum part. Type III Hardcoat Anodize. You have to chemically.

Source: finishingandcoating.com

Source: finishingandcoating.com

If you need functional aluminum parts that will face corression or wear such as aircraft parts or consumer goods this post-processing technique will satisfy your needs. You can get clear anodized but its still a light straw gold color. 7000 Series Aluminium Alloy Zinc This series is alloyed primarily with Zinc. Type II Sulfuric acid anodize has a thickness of 00002 to 0001 inches and is better suited for dyeing parts. Its dunked in dye RIT dye works and then boiled to seal in the color.

Source: finishing.com

Source: finishing.com

Type II anodization is best suited for aluminum but it may also be used for nonferrous metals such as titanium or magnesium. If you have anything you want seriously wear resistant you need massive current for type 3 hard coat annodized. A marbled piece is d. Yes you can but the current he lists here is too low to be hard-coat so it is not the same as buying one anodized. Various color combinations are offered.

This site is an open community for users to share their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site good, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title can you anodize aluminum twice by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.